Aviya’s Virtual Closed Loop Bench (vCLB)

The Challenge:

A large aerospace customer facing challenges in reducing time to market and engineering costs, looked for new ways to better couple the development and certification processes. A tighter workflow would reduce overlap, enhance earlier detection of issues, and reduce costs.

Having worked on numerous programs with this customer, Aviya’s expertise and experience came into play to assist with these challenges.

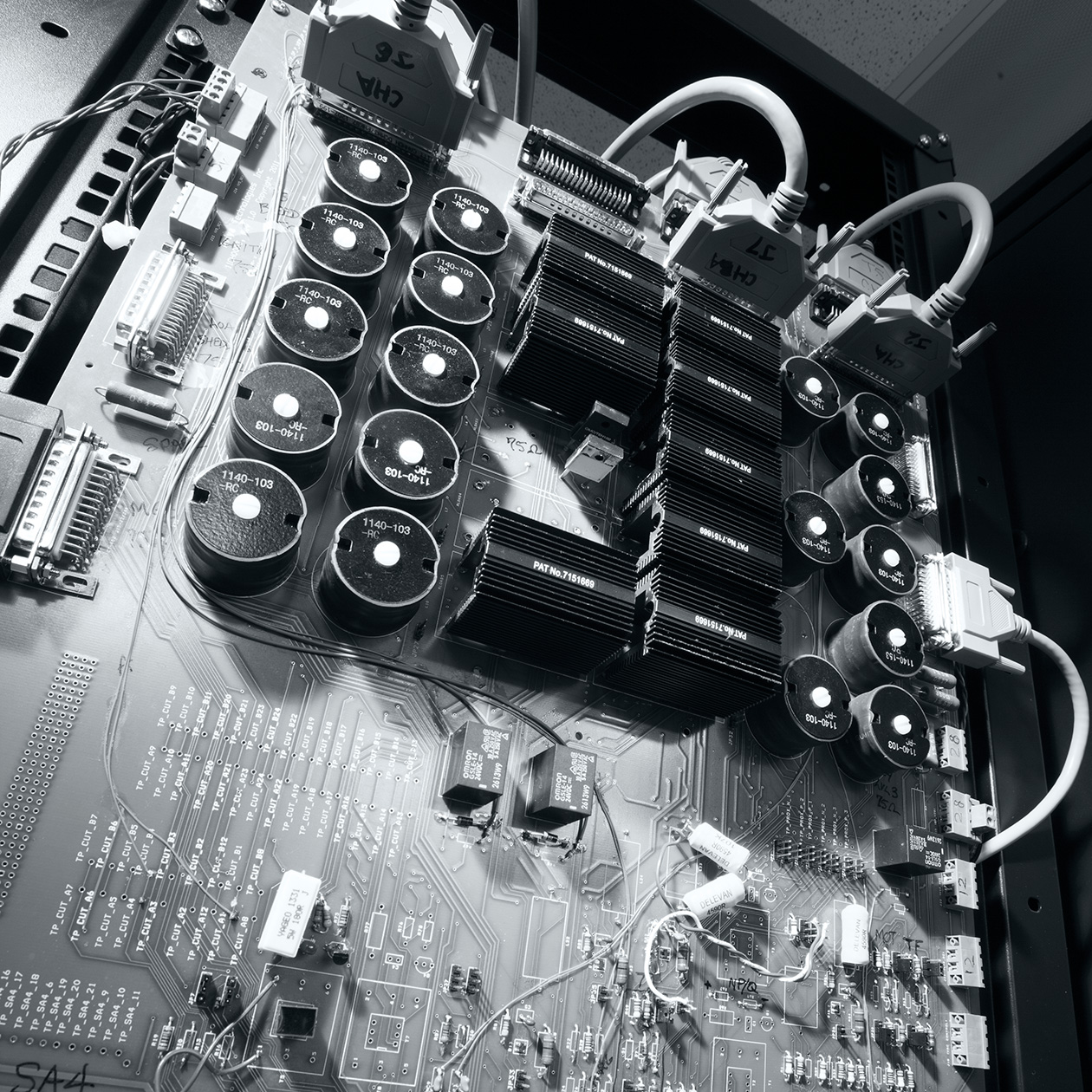

Aviya’s Closed Loop Bench (CLB) platform had been used extensively by this customer for Verification and Validation of their systems to DO-178B Level A. The CLB provides a high-fidelity simulation of the aircraft system environment to allow steady-state and dynamic testing to determine system behaviours and to perform requirements-based testing.

The CLB interfaces a customer’s electronic controller with Aviya’s proprietary hardware simulation environment that mimics the behaviour of sensors and effectors from the aircraft. This real time environment is integrated into Aviya’s powerful GUI-based software interface that allows intuitive script development for complex test scenario creation in a repeatable format.

The CLB is dependent on availability of the controller hardware, even though controller software may be available at an earlier stage in the development process. Aviya’s R&D group was tasked with enhancing the effectiveness of our CLB technology by pushing its benefits further up the development process—well before availability of controller hardware.

The Solution:

The result of this effort is the Virtual CLB (vCLB). The vCLB provides a software environment with the exact same look and feel as Aviya’s CLB, allowing full exercising of the controller software without need for hardware. Availability of a CLB-like environment early in the development cycle now provides another powerful tool for systems and software engineers to test their designs with the same high fidelity as the CLB.

The Benefits:

Since the vCLB shares the exact same GUI-based interface as the CLB, scripts developed in the early stages of the development cycle with the vCLB can be executed on the CLB platform once controller hardware is available. The V&V team can now commence script development for requirements based testing much earlier in the process, allowing level-loading of resources and reducing potential certification risks. Not only are issues in the controller software caught earlier in the process by the V&V team, but system and software engineers can also utilize these same scripts along with their own user developed scripts to informally test their control designs.

With the vCLB, an overall reduction in cost and time in the development and certification process occurs as true value-added testing begins early in the process, not only reducing the number of controller software formal releases, but also reducing the overall test effort required to complete certification.